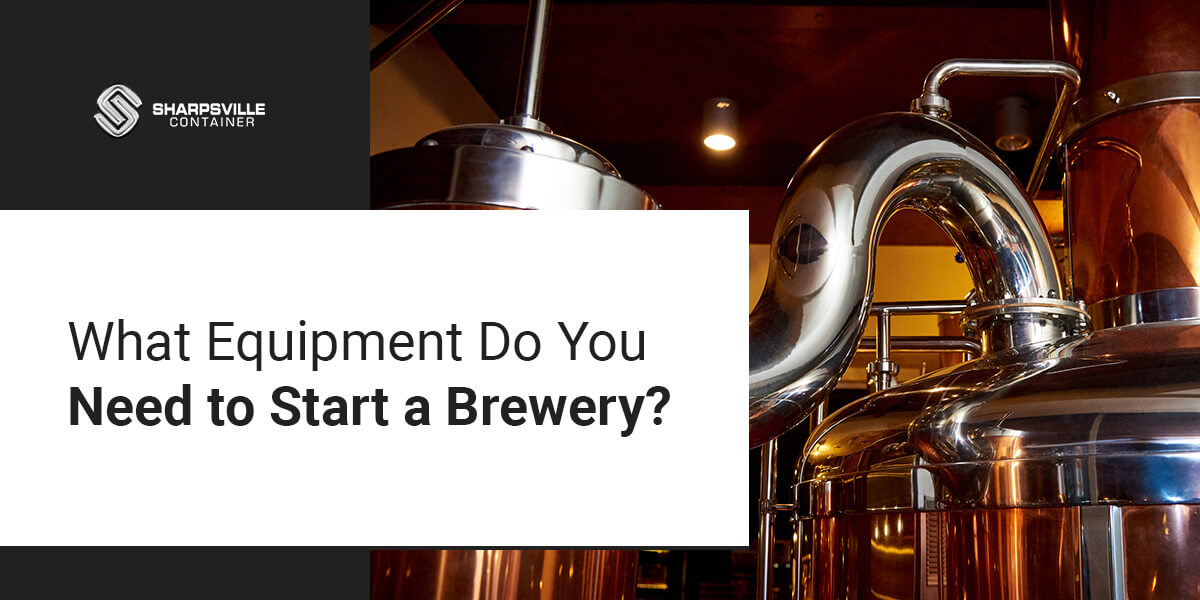

What Equipment Do You Need to Start a Brewery?

Growing your brewery and enjoying the fruits of your labor is rewarding. No matter how you measure success, many elements contribute to your brewery’s growth. One factor at the top of that list is equipment. Knowing what equipment you need to start a brewery or to expand your operations is key.

How Do You Start a Microbrewery?

Starting your own microbrewery is no small feat. It takes dedication, trial and error and a little bit of luck. Thankfully, with these five clear steps, you can be well on your way to creating your own craft beers:

- Define and set your goals: The first key to success is creating measurable goals for your brewery. Start by asking yourself simple questions that can help streamline your process. What are your short-term and long-term goals regarding size and distribution? What kind of beer would you like to focus on? What do you want your brand story to be?

- Think about financing: Having a brewhouse and brewing equipment can be quite expensive and chances are that you may need some financing to get your dream off the ground. Explore where you can source your startup funds — whether that is a loan, from investors or a combination of both. If taking a loan, carefully consider a viable payment plan.

- Choose the right location: Your brewhouse’s location is everything. You will need a space suitable for operations, big enough to house all your equipment and with room to expand. You also need to consider logistics, such as accessibility for delivery trucks and how extensive building alterations will be. Most importantly, you also want a great location you can use for tours and taprooms.

- Work with the right people: Your partnerships with other professionals are what will truly set you up for success. For the best beer and smoothest processes, work with a brewmaster. Work with brand strategists and distribution partners to create a recognizable product that people buy. And most importantly, team up closely with attorneys who can help you sort out the legal nitty gritty so you have a compliant brewery.

What Do You Need to Brew Beer?

Brewing your craft beer necesitates the right equipment for your needs and scale of operations. This brewery equipment list is a great starting point to ensure you cover the essentials:

Brewing and Cellar Systems

Your brewhouse equipment must include the following for producing commercial beer:

- Mash tun: This component is for mixing water and malt.

- Lauter tun: The lauter tun is like a sieve that separates the wort from the malt.

- Brew kettle: The brew kettle is for boiling and sterilizing your liquid. You also add your hops to the brew kettle.

- Whirpool vessel: This vessel separates the hops and other solid particles from the wort after boiling.

- Fermenters: For the fermenting process, you will need a big, stainless steel tank that is suited to the fermentation process. The tanks must withstand pressure and be rated for the type of beer you will produce.

- Brite tank: These temperature-controlled, pressure-rated tanks hold beer after fermentation. A corrosion-resistant, durable beverage storage tank is a good option. These tanks are durable and easy to sanitize.

- Cellar control system: A cellar control system is the brain of your operation. The system helps monitor and control fermentation temperatures and other metrics. It also helps unify your fermentation and brite tanks with your cooling system.

- A kegging system: Kegging systems help you store, carbonate and serve your beer, making them essential components for your taprooms. These Corny Kegs are ideal for brewing in small batches and storing yeast. They allow you to lower the keg’s pressure manually and do not need bottling to dispense. All these features make them a dream to use, especially for smaller startups.

Water Treatment and Supply System

Having clean, filtered water is essential. Water supply systems typically consist of the following:

- A reverse osmosis (RO) filter system

- Stainless steel tanks for preparing, storing and distributing hot water used for the wort brew process and for cleaning the rest of your equipment

- A stainless steel bulk fluid storage tank for the cold water you will use to cool the wort

- Industrial boilers and steam pipes for connecting to your hot water tanks

- Glycol unit and pipes for connecting to your cold water system

- Water supply pumps

Safety Accessories

Last but definitely not least, you want a brewery that is as compliant and safe as possible. A significant part of this includes having the necessary safety accessories and personal protective equipment (PPE) for your team. This includes items such as:

- Work gloves

- A face shield

- Aprons and smocks

- Hearing protection

Of course, you will need other accessories to have a fully operational brewery, including standard kitchen accessories, a bottling setup and products like bottle or can labeling machines.

Choosing Equipment for Your Brewery: FAQ

Explore the answers to these frequently asked questions regarding brewery facilities, equipment costs and customization options:

Do I Have the Right Facility to House Commercial Beer Equipment?

Even for a microbrewery, space is a significant consideration. Brewing and storing beer requires large components like stainless steel storage tanks and heating and cooling systems. Your potential brewhouse should also have the proper ventilation, drainage and electrical setup for your operations.

How Much Does Brewery Equipment Cost?

The reality is that brewing equipment can be expensive, but for a microbrewery startup, choosing quality equipment such as stainless steel storage vessels, tanks and kegs will save you in the long run. Exact costs also depend on various other factors like the size of your brewery, if you buy new or used equipment, who you are purchasing from (which will affect the quality of what you purchase), how much you automate the process and what type of beer you will brew.

Can I Customize My Brewery Equipment?

The good news is that you can definitely customize some of your brewery equipment. With Sharpsville Container, you work with a team of professional in-house engineers and designers who will create custom beverage storage units that suit your needs.

Get Custom Manufactured Stainless Steel Vessels and Kegs From Sharpsville Container

Get started with high-quality, custom-manufactured stainless steel tanks, vessels and kegs for your microbrewery from Sharpsville Container. At Sharpsville Container, our engineers and designers specialize in fabricating and assembling premium stainless steel containers customized to your business needs.

We ship nationwide and internationally to serve our clients no matter where they are. Contact us today for a quote on any of our standard tanks, vessels or kegs or discuss custom options for your microbrewery.