Sharpsville Container Corporation manufactures many types of high-pressure gas cylinders for various industries. Choose from many types of cylinders, or get a custom high-pressure cylinder designed for your application.

About High-Pressure Gas Cylinders From Sharpsville Container

High-pressure tanks contain and store gases at higher pressures than in the atmosphere. This level of pressure places the bottle’s contents in a state of supercritical fluid, dissolved or substrate material, vapor over liquid, or compressed gas. The valve and nozzle at the top of the bottle release the gas in a controlled way. You can also connect a reception mechanism to the valve.

Though these cylinders can be made from many materials, high-pressure cylinders from Sharpsville Container have a carbon steel or stainless steel construction. These materials are durable, stay intact after impact and have high mechanical strength. These metal alloys also do not corrode and will resist rust. These qualities are ideal for providing protection, as these cylinders are often present in work environments involving collisions, cutting tools, open flames and heavy machinery.

Our custom high-pressure cylinders also meet these qualifications:

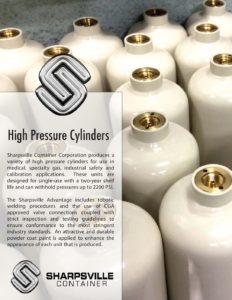

- Service pressures up to 2200 PSIG

- Size options up to 277 cubic inches (water capacity)

- Complete traceability of raw materials, cylinder lot numbers and test results

Our Cylinder Certifications

Our cylinders meet various industry certifications for quality. They are produced in accordance with:

- DOT 39 – Hazard Class/Division 2.1 or 2.2

- Transport Canada Certificate No.: SU 6495 (Ren. 3)

- Transportable Pressure Equipment Directive (TPED)

Types of High-Pressure Cylinders

We offer many types of high-pressure cylinders, including:

- Non-reactive gas cylinders: These containers are designed for non-reactive gases. We manufacture non-reactive carbon steel cylinders with girth welding — our M-Series — and straight sides — the T-Series.

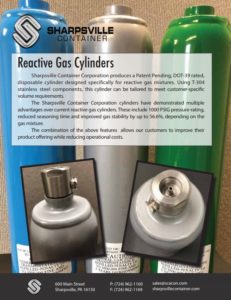

- Reactive gas cylinders: Reactive gas cylinders are disposable containers for reactive gas mixtures. These bottles are made from stainless steel.

- Medical cylinders: Medical cylinders are designed for medical gas applications. We have girth-welded M-Series and straight-side K-, D-, T- and E-Series construction available. Sizes go up to 229 cubic inches, with custom sizes on request.

- Specialty cylinders: Specialty gas cylinders are single-use cylinders for technical applications. These containers can reach service pressures up to 2,200 PSIG, with many custom engineering options available to meet your requirements.

Applications for High-Pressure Cylinders

A DOT 39 cylinder can store many types of gas substances, including:

- Oxygen

- Hydrogen

- Helium

- Fluorine

- Nitrogen

- Argon

- Silicon hydrides

- Krypton

High-pressure cylinders also store gases that liquify under high pressure, such as:

- Carbon dioxide

- Sulfur dioxide

- Butane

- Ammonia

- Nitrous oxide

- Propane

These tanks are ideal for applications where safe transportation and storage of compressed gases is required. Common use cases for high-pressure stainless steel cylinders include:

- Medical

- Specialty gas

- Industrial safety

- Calibration applications

Request a Quote for Your Custom High-Pressure Cylinder

Choose Sharpsville Container for all of your high-pressure cylinder needs. We can design custom high-pressure cylinders for your business to meet your unique requirements. We also have a full-time, third-party DOT Inspector on-site and provide individualized customer service.

To learn more or get answers to any questions you may have, request a quote online, call 724-964-4098 or contact us on our website today.