Transporting and storing materials can be much more complicated than simply finding a drum or tote and filling it with your contents. The United States Department of Transportation (DOT) and the United Nations (UN) have specific guidelines that companies must follow to comply with their regulations. However, it isn’t just red tape — these rules ensure the public, transportation workers and the environment stay safe and remain healthy and productive.

To make sure you’re ready for your next DOT inspection, we’ve put together some of the more common definitions and rules required so you can be fully prepared to select your shipping or storage containers and ensure they are ready for their next voyage to or from your warehouse.

What Does DOT-Approved Mean?

DOT-approved shipping containers are transport vessels that meet the DOT’s current standards for safely shipping hazardous and other materials. DOT shipping containers must be designed to securely transport high-risk materials, such as fluids and gases, to ensure that they arrive safely.

Safety threats when shipping certain materials can include fire, explosions, corrosion, infections and other hazards. Transporting hazardous materials (hazmat) in a U.S. DOT-approved shipping container greatly reduces the risk of these threats becoming a reality.

Container Requirements for DOT Approval

The DOT rating system uses a set of codes to determine whether a container meets the required safety parameters for use in transportation.

DOT-rated containers are typically required for transporting materials that pose a higher-than-average risk, which the Department refers to as “hazardous materials.” These containers are specifically designed to sustain extreme forces such as:

- Vibration.

- Impact.

- Extreme temperature.

- High pressure.

DOT-rated containers are unlikely to crack or rupture in an accident — which could potentially save lives.

How Does the US DOT Define ‘Hazardous Materials?’

The DOT defines hazardous materials as having the potential to cause threats like fire, explosions, or other health and safety risks. The DOT organizes its hazardous material classification by type of product and determines how that type of material can be shipped.

There are nine DOT classes of hazardous materials, and every hazardous material being shipped is assigned to one of these nine classes. Each of the nine classes may also be subdivided into divisions based on their specific chemical properties, such as whether they are flammable or toxic.

The nine U.S. DOT hazardous material categories are:

- Class 1 — Explosives: There are six divisions of explosive materials, ranging from materials having a mass explosion threat to insensitive materials that aren’t a mass explosion hazard.

- Class 2 — Gases: Transported gases can be rated as flammable, toxic, nonflammable and nontoxic.

- Class 3 — Flammable and Combustible Liquids: Flammable and combustible liquids are rated based on their flashpoint from 0 degrees up to 141 degrees Fahrenheit.

- Class 4 — Flammable Solids: Flammable solids are considered purely flammable, spontaneously combustible or dangerous when wet.

- Class 5 — Oxidizers and Organic Peroxides: Class 5 materials are rated as either oxidizers or organic peroxides.

- Class 6 — Poison (Toxic) Substances and Infectious Substances: Class 6 materials are divided into either poisonous (toxic) materials or etiologic (infectious).

- Class 7 — Radioactive Materials: Any material that spontaneously emits radiation is considered radioactive.

- Class 8 — Corrosives: Corrosives are any liquids or solids that harm human skin or have a high corrosive rate on metals.

- Class 9 — Miscellaneous and Dangerous Materials: Any other material that presents a threat during transportation but doesn’t fit into the above categories is considered class 9.

When shipping hazardous materials, the packaging must be labeled with the appropriate hazardous placard containing the class and division of material. Accurately reporting which materials are contained in the transportation vessels saves lives because it lets cargo handlers know the material’s proper handling instructions. By shipping contents in DOT-approved containers for hazardous waste, you can ensure you comply with DOT regulations — meaning you’ll protect people and the planet.

Understanding the UN/DOT Container Codes and Rating System

There are six components to the UN/DOT container codes, which are separated by a slash on the container. These components include the following.

1. Container Type

Hazmat container types are represented by a number from one to seven:

- Drum

- Barrel

- Jerrycan

- Box

- Bag

- Composite packaging

- Pressure receptacle

The container’s material is indicated by a letter. Some examples include:

- A: Steel

- B: Aluminum

- D: Plywood

- H: Plastic

- L: Textile

- M: Paper

- P: Glass, porcelain or stoneware

Finally, the type of closure (head) is indicated by a number:

- 1 — Closed: The container is permanently sealed, and workers need special tools to open it.

- 2 — Open: The container has a latch that can open and shut.

Therefore, the code for an aluminum jerrycan with a closed head would be 3B1, while a plastic drum with an open head would be 1H2.

2. Packing Group and Capacity

The packing group indicates how dangerous the contents of the container are. There are three hazard levels:

- Group I: Highest risk

- Group II: Moderate risk

- Group III: Lowest risk

The letter in the second part of the UN code indicates which hazards the container is approved to hold:

- X: Can carry items in all three groups.

- Y: Can carry items in groups II and III.

- Z: Only suitable for carrying items in group III.

This section also includes a number, which indicates how much weight the container can hold in kilograms. For example, a container marked Z65 is approved to carry a maximum of 65 kilograms of a low-risk item.

3. Contents

The next character indicates whether the container can hold a liquid or a solid. If it’s an S, the container is only approved to transport solid materials — it is not suitable to hold free liquids.

If the code contains a number instead of an S, then the container is designed to handle liquids. This number indicates the product’s hydrostatic test pressure, which is extremely important for preventing serious damage.

4. Year of Manufacture

The fourth section of the UN packing code contains the final two digits of the year the package contents were manufactured. So, for materials produced in 2024, it would read “24.”

5. Country of Manufacture

Each country has a unique combination of letters in the UN packaging code. For example, the code for products manufactured in 2024 in the United States would say “24/USA.”

6. Manufacturer Code

Finally, the code ends with a unique series of letters and numbers representing the facility that manufactured the product.

DOT-Approved Container Types

DOT-rated containers are used to transport materials by road, rail, air or sea.

What makes the DOT/UN rating so important is the safety requirements, which greatly increase the container’s ability to undergo disruptive conditions and remain intact and not spill or leak its contents.

To get a better understanding of how the DOT and UN rating system affects containers’ design, we will explore the different types of containers.

Drums

Drums are one of the most popular DOT container types due to their easily transportable size and stackable design. Many companies use drums to store and transport a wide variety of liquid and semi-liquid materials.

The biggest reason companies choose to use drums to store materials on-site is their unique dimensions allow them to be stacked on top of each other and remain secure and stable. Also, drums typically use a latch lid system, allowing them to remain completely sealed if they get tipped over.

Although drums come in many sizes ranging from 15 gallons to several hundred gallons, the 55-gallon drum is considered the most popular. The 55-gallon drum was developed in the 1850s during the oil prospecting era in Pennsylvania. Oil prospectors selected 55 gallons or 45 imperial gallons due to the ideal compromise between storage weight and maneuverability. At this weight, a person could move it around by themselves using a wheel dolly.

The drum’s material depends on the drum’s contents and the desired service duration of the drum. For hazardous contents, the drum must consist of material that the contents cannot degrade or interact with chemically. For instance, steel drums are often used to transport or store petroleum products, such as crude oil or diesel fuel, rather than wood. Steel is much better at resisting the degrading effects that petroleum products often have on wood.

A big consideration of the DOT/UN rating for drums is to ensure that the drum will not fail in any way during transportation. To accomplish this, DOT codes specify certain design requirements for drum manufacturers, including:

- Material selection.

- Drum thickness.

- Latch or closing mechanism.

In addition to design requirements, DOT/UN ratings also include strict rules for drum labeling. These labels specify which of the nine DOT classes of hazardous materials the drum contains. Labels must also follow the size and color requirements from the DOT/UN convention.

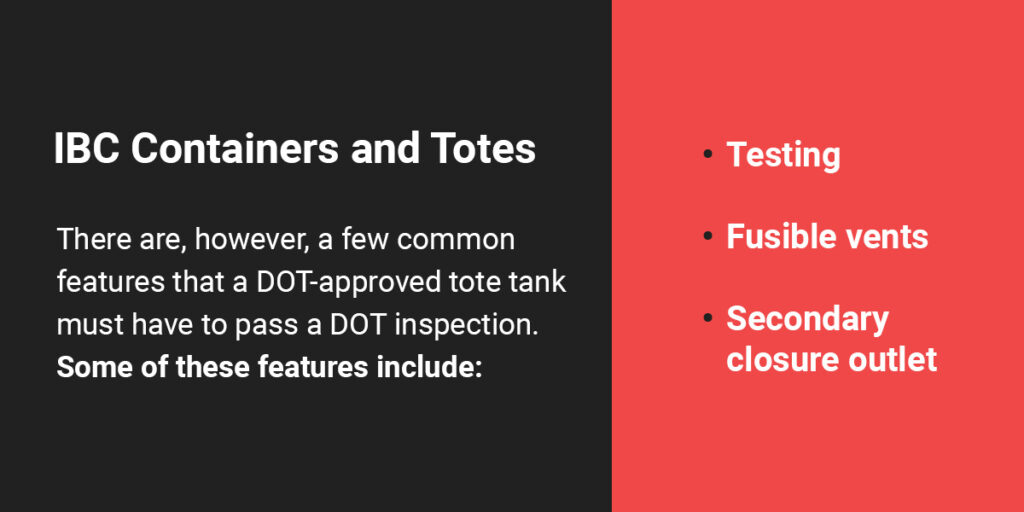

IBC Containers and Totes

When it comes to DOT- and UN-rated intermediate bulk containers (IBCs) and tote tanks, stainless steel tanks are usually preferred due to their increased toughness and resistance to failure compared to plastic containers.

There are, however, a few common features that a DOT-approved tote tank must have to pass a DOT inspection. Some of these features include:

- Testing: Every tote must undergo a leak-proof test and an extensive visual inspection once every 30 months. It also must undergo a thickness test every 60 months, which involves measuring the tank’s thickness to ensure structural safety.

- Fusible vents: In a fire or other extreme circumstance, the fusible vents break and allow pressure inside the tank to escape in order to prevent a catastrophic explosion. These vents are typically 3 inches in diameter, located on top of the tote container and are different from normal pressure relief valves.

- Secondary closure outlet: DOT requirements state that the drain valve on the bottom of the IBC or tote must have a secondary mode of opening to ensure contents can escape. Threading another release valve into the cap of the first valve is typically sufficient to meet this requirement.

Packaging for Radioactive Contents

When transporting contents that might be radioactive, it’s essential to use DOT-approved waste containers. In addition, the DOT requires that special precautions be taken. First, the material must be classified into one of three categories:

- Industrial packaging

- Type A packaging

- Type B packaging

Objects that might be slightly contaminated with radioactive material, such as clothing, laboratory samples and smoke detectors, must be transported in industrial packaging. Industrial packaging is defined as “strong and tight containers.” Although this definition doesn’t give an exact prescription of the packaging requirements, it’s safe to assume that a secure and robust container should be acceptable.

DOT Type A containers are required for materials with a higher specific activity level, meaning materials with more radioactive intensity than materials requiring just industrial packaging. Type A packaging must withstand various tests without releasing any of the radioactive materials contained within them. Typical contents that require DOT Type A shipping containers include radiopharmaceuticals and certain regulatory-qualified industrial products.

DOT Type B containers are reserved for materials that exceed the limits of Type A packaging requirements. Items that require Type B packaging include any materials that would present a radiation hazard to the public or environment if a major release from them should occur. This means Type B packaging needs to withstand testing during normal transportation of radioactive goods and testing that simulates a catastrophic accident during the transportation of those goods. Type B packaging is reserved for materials containing a high level of radioactivity, such as spent fuel from nuclear power plants.

Recertification for DOT-Approved Containers

If you plan to reuse a DOT-approved container, you’ll need to receive recertification to verify that it still meets operational standards for the material it will transport. Depending on your specific circumstances, recertification may be either a formal process requiring specialized professionals or an in-house procedure completed by a trained employee.

In addition to the DOT requirements, other standards, such as the following, may apply:

- American Society of Mechanical Engineers (ASME)

- National Sanitation Foundation (NSF)

- Transportable Pressure Equipment Directive (TPED)

- Steel Tank Institute (STI)

- American Petroleum Industry (API)

The specific regulations you need to certify will vary depending on container type and material.

Choose Sharpsville Container for Custom DOT Approved Containers

For high-quality, DOT-approved shipping containers, choose Sharpsville Containers. Since we’re an ISO 9001 company, you can rest assured that our containers are expertly engineered and tested to ensure our customers meet DOT shipping standards for all materials, including hazardous contents.

Serving a wide range of industries, including food and beverage, dairy, pharmaceuticals and more, Sharpsville Containers offers a broad range of containers to meet your needs. In addition to stainless steel tanks, high-pressure cylinders, UN/DOT transport vessels and reactors and fermenters, we also offer custom engineering solutions so you can get the exact container for your application.

For more information on our products and the markets we serve, contact us today or request a quote for your next project.

Leave a Reply